Republic Power Systems Ready For Launch

GEORGETOWN, TX., Feb 5, 2018 – Republic Power Systems, a new company providing electrical power conditioning and battery backup solutions is set to launch this month. RPS is poised to fill a gap in the Uninterruptable Power Supply (UPS) market space for commercial, industrial, medical and military applications. Partnering with Sanyo Denki, a recognized leader in power products for over 90 years, Republic Power Systems will offer a line up of Uninterruptible Power Supply (UPS) products that are designed and manufactured to the highest quality ISO 9001 standards, are a revision-controlled and while robust in design, remain cost-effective.

As noted by RPS President/CEO Steve Travis:

Over the years working in the military and industrial market spaces I have seen that there is a niche market space between standard “consumer grade” products and fully ruggedized equipment. In such cases, a durable, cost-effective product with the potential for customizations, tailored to the customer’s specific requirements can be a winning combination.

As advances in technology continue to be introduced and integrated into all aspects of life, the UPS will continue to play a critical role in protecting present as well as future electrical equipment. In fact, the UPS worldwide market is projected to grow CAGR 7.5% between (2017 – 2025). An Uninterruptable Power Supply protects electrical equipment from damage from power surges, sags, or complete loss of power. These power condition issues can come from utility, problems with building internal infrastructure or inclement weather as examples. By isolating critical equipment from utility power, the UPS provides clean, efficient, stable electrical power 7/24.

About the writer: Steve Travis President & CEO of Republic Power systems is a seasoned professional in the military and industrial market spaces. As a founding partner in Chassis Plans LLC, he has over 20 years of experience understanding the requirements and expectations involved with highly complex projects. Mr. Travis’ strength is also in his ability to surround himself with like-minded professionals when building a customer-centric business organization such as Republic Power Systems.

For more information about this or any other topic, please contact:

How To Properly Maintain a UPS

Because of the critical role that the UPS provides, it is important that basic scheduled maintenance is performed to ensure optimal performance and protection capabilities of a UPS platform are in place and ready. This article will cover three basic areas of UPS maintenance, diagnostic testing, the overall UPS physical structure and the UPS battery itself. Due to the numerous applications and installed environments for UPS products, this article will only cover the recommended basics allowing the customer to assemble a maintenance schedule appropriate for their own unique operating environment.

DIAGNOSTICS

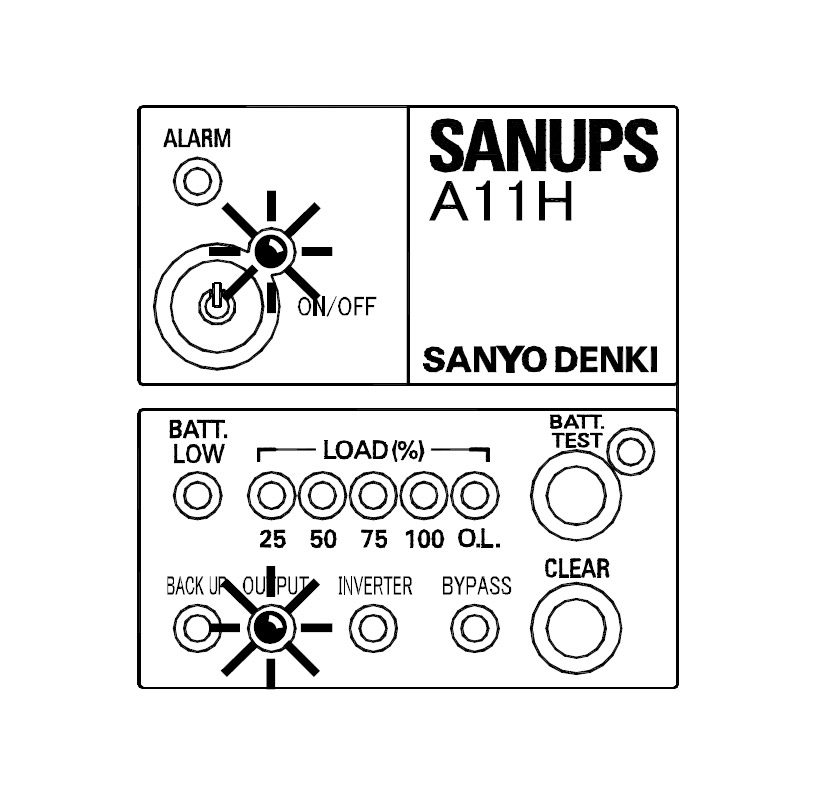

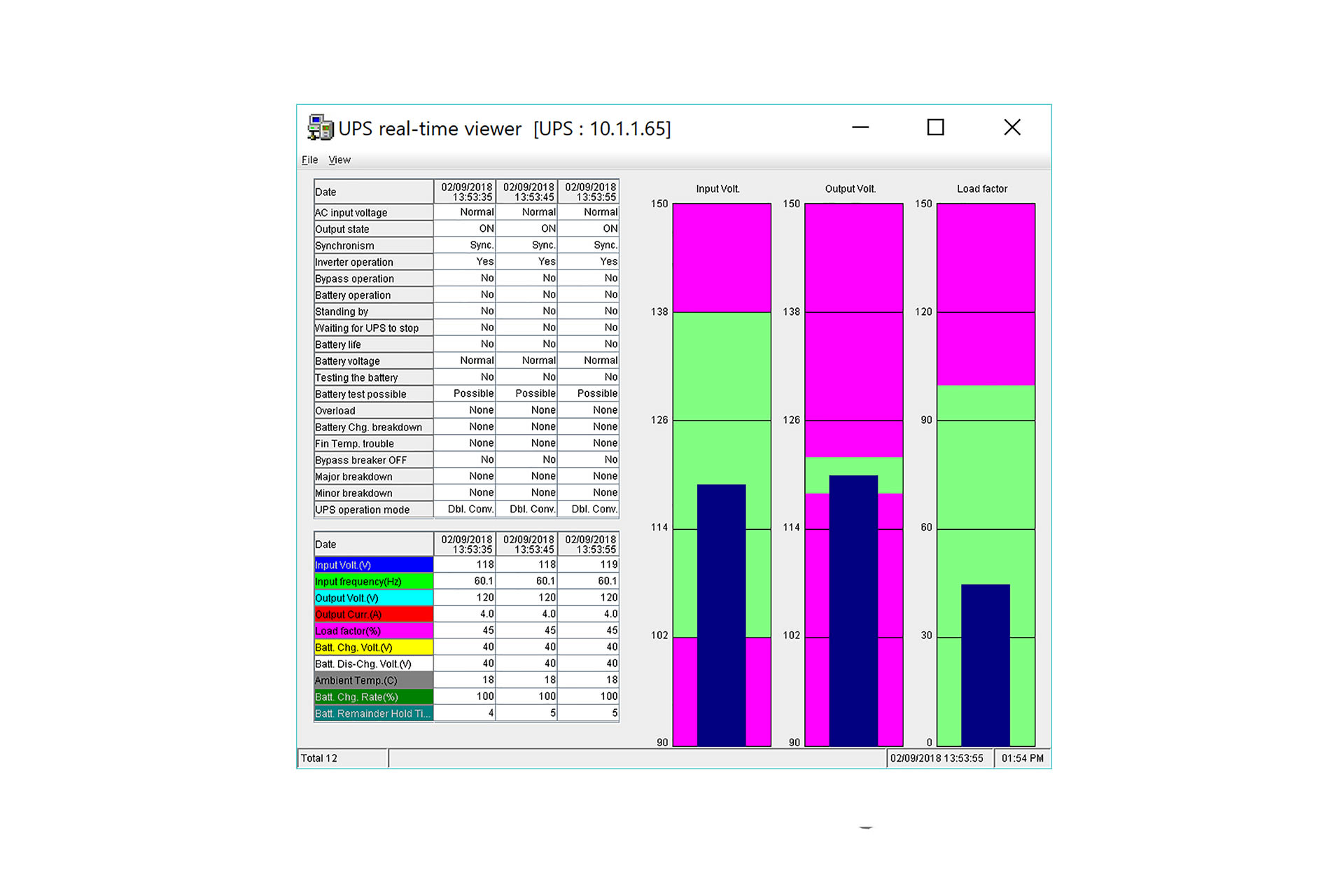

SANUPS UPS products have two forms of diagnostic capabilities. They are visual and audible alerts and software communications from the UPS. It is recommended to utilize both visual as well as software monitoring in the overall maintenance plan of a UPS.

Visual Inspection

Each SANUPS product comes equipped with front panel indicators either in the form of LED indicators or an LCD panel. For best practices a simple visual inspection of these displays should be performed daily, but no longer than weekly. Functions to be verified include:

Each SANUPS product comes equipped with front panel indicators either in the form of LED indicators or an LCD panel. For best practices a simple visual inspection of these displays should be performed daily, but no longer than weekly. Functions to be verified include:

- Unit is powered on, no unusual noises coming from unit or smells being emitted.

- No current alarm events, from front panel indicators or audible alarm.

- Battery load is optimal

- Battery Testing can also be manually be performed from the front panel or through software interface (Recommended every 6 months)

Software Monitoring

Utilizing SANUPS monitoring software, along with visual inspections will help to ensure system reliability for years to come. Depending on software and integrated hardware, multiple points of temperature and humidity can be monitored, power events detected and logged, and battery performance can be monitored. Events can be configured to trigger email alerts to designated employees. Additionally, this software provides automatic shut-down of target equipment, if utility power has not been restored before the UPS battery loses its remaining charge.

Utilizing SANUPS monitoring software, along with visual inspections will help to ensure system reliability for years to come. Depending on software and integrated hardware, multiple points of temperature and humidity can be monitored, power events detected and logged, and battery performance can be monitored. Events can be configured to trigger email alerts to designated employees. Additionally, this software provides automatic shut-down of target equipment, if utility power has not been restored before the UPS battery loses its remaining charge.

EXTERNAL INSPECTION

Due to a UPS’s size and weight, it is generally installed in the lower portion of a rackmount frame or directly mounted to the floor. Because of these mounting locations, visual inspection is vital to ensure continued operation. The potential for the intake of dirt & dust as well as physical damage is much higher in these lower mounting positions.

Air Intake and Exhaust

Because mounting is low to or on the floor for mounting a UPS, the air filter (if equipped) must be checked regularly to ensure proper air flow to the UPS. Over time, if the air filter becomes clogged with dust and debris, cooling fans will increase speed, causing additional power drain as well as increase noise as they try to extract as much air as they can from clogged filter media. This has a greater potential impact on overall system performance and battery life from increased internal system temperatures. Recommended cleaning intervals is dependent on the installed environment.

Because mounting is low to or on the floor for mounting a UPS, the air filter (if equipped) must be checked regularly to ensure proper air flow to the UPS. Over time, if the air filter becomes clogged with dust and debris, cooling fans will increase speed, causing additional power drain as well as increase noise as they try to extract as much air as they can from clogged filter media. This has a greater potential impact on overall system performance and battery life from increased internal system temperatures. Recommended cleaning intervals is dependent on the installed environment.

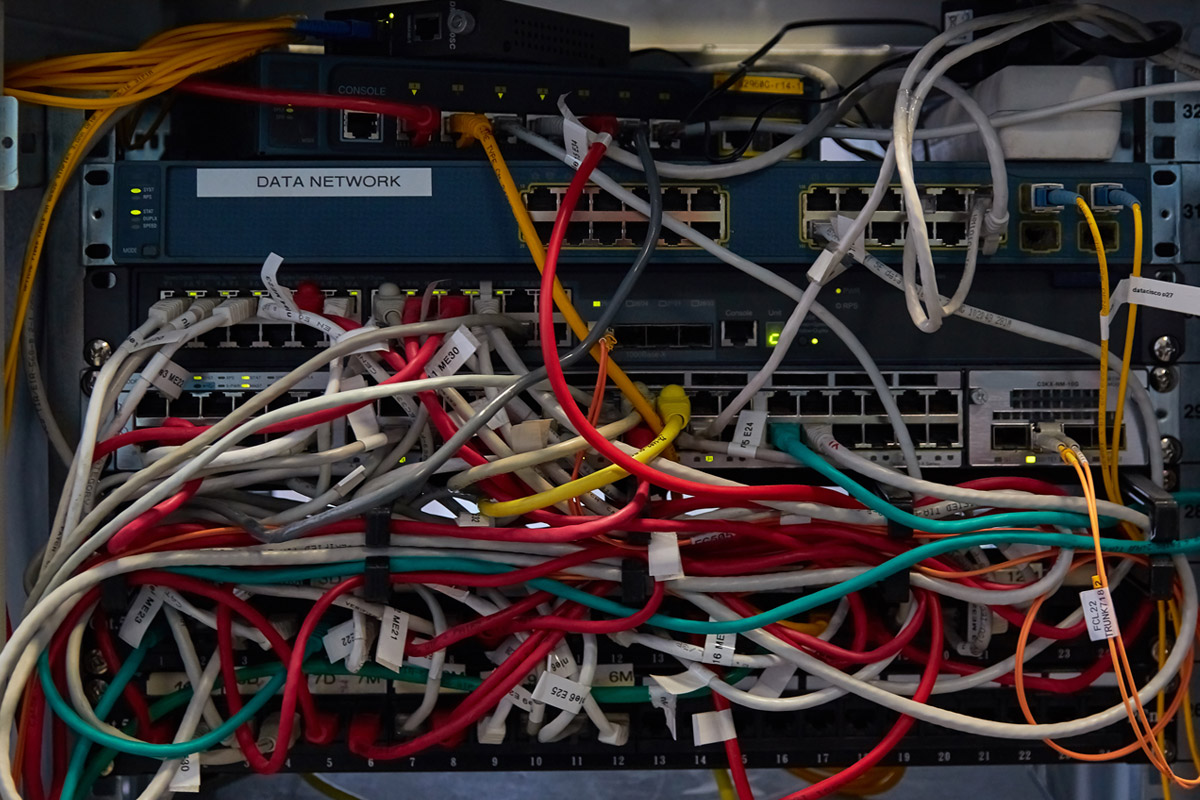

Along with keeping the filter media clean, it is essential to verify that nothing is blocking either the air intake or exhaust ports of the UPS itself. Depending on the installed location, over time new equipment may be introduced, additional cable runs added that might “drape” over critical areas of the UPS. Additionally, air flow or exhaust may become blocked temporarily such as boxes being stacked or moving equipment placed in front of the UPS.

Along with keeping the filter media clean, it is essential to verify that nothing is blocking either the air intake or exhaust ports of the UPS itself. Depending on the installed location, over time new equipment may be introduced, additional cable runs added that might “drape” over critical areas of the UPS. Additionally, air flow or exhaust may become blocked temporarily such as boxes being stacked or moving equipment placed in front of the UPS.

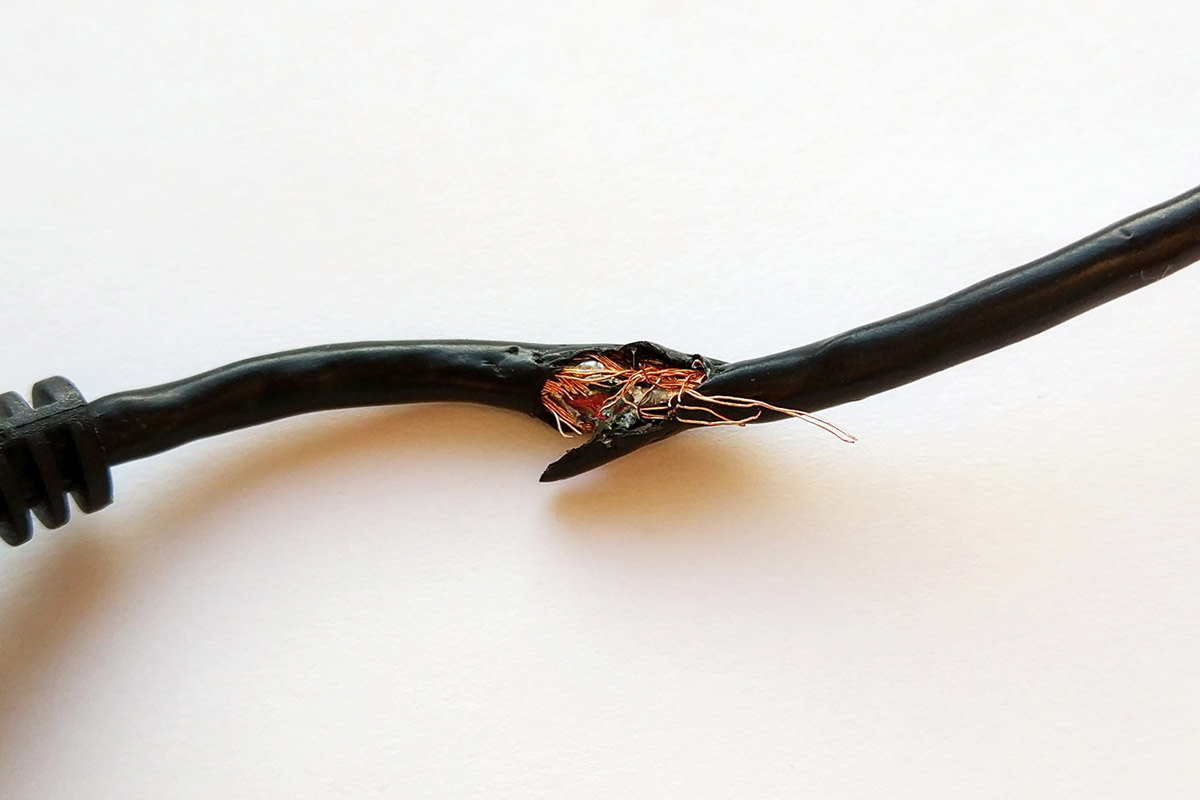

During the physical inspection process, cabling to the UPS system itself should also be inspected. Wiring can become unplugged or damaged over time. Depending on how wiring was initially been routed, and or if cable management was utilized, all play a factor in the protection and positive connection of power output cables from the UPS.

During the physical inspection process, cabling to the UPS system itself should also be inspected. Wiring can become unplugged or damaged over time. Depending on how wiring was initially been routed, and or if cable management was utilized, all play a factor in the protection and positive connection of power output cables from the UPS.

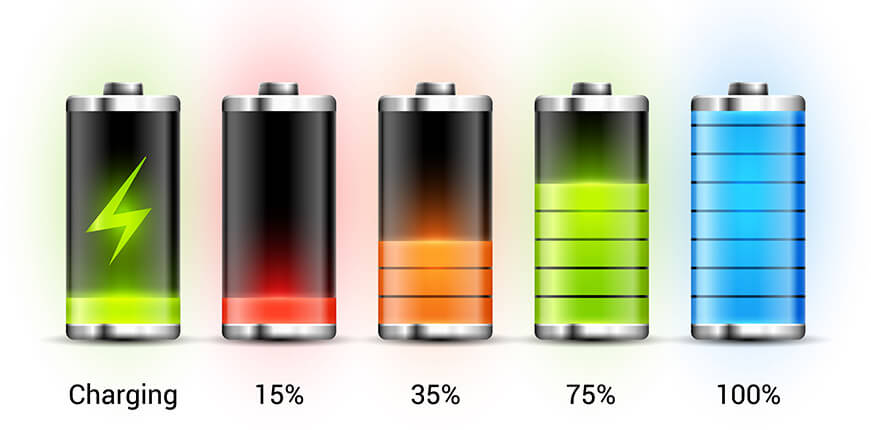

UPS BATTERY MAINTENANCE

Several aspects of a UPS battery must be known to ensure continued performance and maximized battery life for the UPS. The battery’s life can be affected by ambient operating temperatures, constant power “cycling”, operational wear and tear of the battery itself and how batteries are stored when not in operation. All issues must be taken into consideration when putting together a maintenance plan.

Ambient Operating Temperature

Internal and external VRLA batteries have a rated capacity based on an ambient temperature of 25°C (77°F). Operating the UPS and its batteries under these conditions will maximize the life of the UPS and result in optimal performance. While a UPS will continue to work in higher temperature ranges, it will result in diminishing battery performance and lifespan, as indicated in the chart below.

| Ambient Operating Temperature | Battery Replacement Interval |

|---|---|

| 25°C (77°F) | 4.5 years |

| 30°C (86°F) | 3 years |

| 35°C (95°F) | 2 years |

| 35°C (95°F) | 1.5 years |

Cycling

When a loss of power occurs, the UPS will switch to battery power, continuing to supply critical equipment (load) energy. Once the utility power has been restored the UPS battery begins its recharge preparing for the next potential power outage. A process known as the “cycling”. The chemistry makeup of a VRLA battery dictates it can only undergo so many discharge/recharge cycles before it reaches its’ end of life, and must be replaced. If your UPS is subject to numerous “loss of power” events, the battery(s) must be monitored at a closer rate to ensure for continued backup protection.

When a loss of power occurs, the UPS will switch to battery power, continuing to supply critical equipment (load) energy. Once the utility power has been restored the UPS battery begins its recharge preparing for the next potential power outage. A process known as the “cycling”. The chemistry makeup of a VRLA battery dictates it can only undergo so many discharge/recharge cycles before it reaches its’ end of life, and must be replaced. If your UPS is subject to numerous “loss of power” events, the battery(s) must be monitored at a closer rate to ensure for continued backup protection.

UPS Battery Maintenance

VRLA batteries are classified as “Maintenance-free” as they do not require electrolyte replacement and because they are double sealed will not leak. However, they do require periodic maintenance in the form of visual inspection. Visually inspect batteries for cleanliness and remove any dust and debris, checking for loose connections, and potential corrosion on the battery terminals. Lastly batteries displaying excessive swelling are an indicator of being at “end of life” and should be appropriately disposed of and replaced.

VRLA batteries are classified as “Maintenance-free” as they do not require electrolyte replacement and because they are double sealed will not leak. However, they do require periodic maintenance in the form of visual inspection. Visually inspect batteries for cleanliness and remove any dust and debris, checking for loose connections, and potential corrosion on the battery terminals. Lastly batteries displaying excessive swelling are an indicator of being at “end of life” and should be appropriately disposed of and replaced.

Battery Storage

When storing extra UPS batteries as there are a few important factors to consider when placing your UPS battery into storage or the UPS itself is not in use. Over time the batteries will self-discharge, it is recommended that batteries in long term storage be charged every 2 to 6 months depending on ambient storage temperature as indicated on the chart below:

| Average Ambient Storage Temperature | Battery Re-Charge Interval |

|---|---|

| 25°C (77°F) | Once every 6 months |

| 30°C (86°F) | Once every 6 months |

| 40°C (104°C) | Once every 2 months |

UPS MAINTENANCE CHECKLIST

Scheduled monitoring and maintenance of a UPS greatly reduces the chance of failure to supply power to connected critical equipment. In most cases daily simple observation is recommend both visually as well as monitoring through the SANUPS software. Listed below are the basics in developing a checklist and recommended intervals. Ultimately, end users will determine best practices for their operating environment. This checklist should be used as a guideline.

Visual Inspection

- Confirm ambient operating temperature and humidity are at target levels (Daily)

- Review UPS operational status (Daily)

- Front panel indicators are nominal

- No audible alarms coming from UPS unit

- No unusual noises or smells emitted from UPS

- Air Flow and exhaust (Weekly/Monthly/Quarterly depending on environment)

- Inspect, clean and or replace air filter media

- Verify proper airflow and exhaust are clear of obstructions as per operations manual

- Perform dusting and vacuuming of UPS and surrounding installed area

- Inspect external cabling (Monthly/Quarterly)

- Locked/positive connection to UPS

- Inspect for wear or signs damage to cabling structure.

- Inspect battery (6 months)

- Confirm integrity of battery enclosure, looking for swelling or damage

- Inspect/Clean battery terminals for corrosion

- Verify positive connection between cabling and battery terminals

- Replace batteries at recommended intervals

Diagnostics

- Review UPS operational logs power events, charge cycles and warning notifications (Weekly/Monthly)

- Run diagnostic battery tests (6 months)

- Off-Line load tests the UPS to ensure the system is entirely functional, return the system to following documented procedures in the user (Yearly)

For more information about this or other UPS related topics please contact us. sales@repubicpowersystems.com or also provide feedback to this blog.